| Availability: | |

|---|---|

| Quantity: | |

DYE-I

DYE

HS Code: 8419409090

Copper Distiller Industrial Alcohol Whisky Distillation Equipment

Maximize your production capabilities with our Copper Distiller, specifically engineered for industrial alcohol and whisky distillation. This premium distillery equipment combines traditional craftsmanship with modern technology, making it ideal for large-scale operations in any whisky distillery.

Constructed from high-quality copper, this Industrial Distillation Equipment ensures exceptional heat conductivity and efficiency, allowing for precise temperature control and optimal flavor extraction. Its robust design not only enhances durability but also provides a classic aesthetic that elevates your distillation setup.

Main Features:

1.Advanced alcohol distillation equipment for high-volume production

2.Superior copper distiller design for optimal performance and flavor retention

3.Ideal for both whisky and other spirit distillation applications

4.Built to withstand the demands of industrial use while ensuring ease of operation

5.Comprehensive solution for all your distillery needs

Elevate your distillation process with our Copper Distiller, the perfect choice for any serious distiller looking to enhance their whisky production and overall efficiency.

Parameter:

| Specification | 500L working capacity pot; all stainless steel pot |

| SS Steam jacketed and insulated | |

| with 219mm handhole with DN51 outlet and valve | |

| With top agitator (explosion proof CE approved motor) | |

| Motor Power: 0.75KW / 60rpm | |

| Copper Cu12200 Gooseneck, 3mm thickness | |

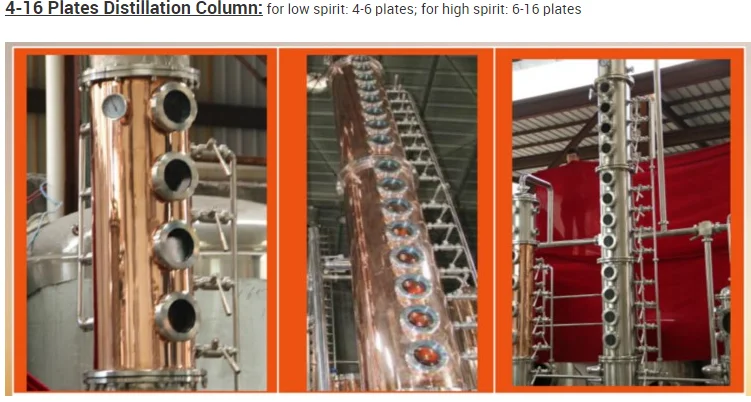

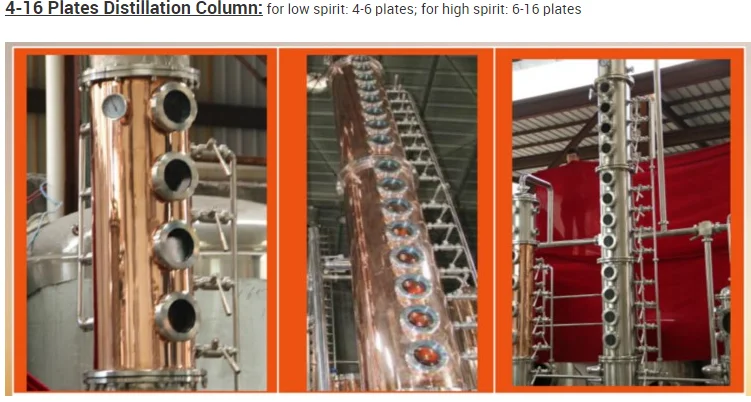

| 300mm Copper Distillation Column, 4 plates copper distillation, each plate has CIP ball and drain valves. | |

| 300mm SS Dephlegmator on the top of column | |

| 300mm SS Condenser | |

| 2 pcs SS Tube Legs | |

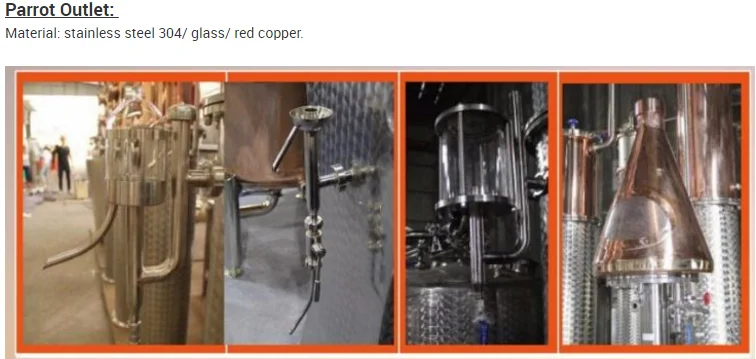

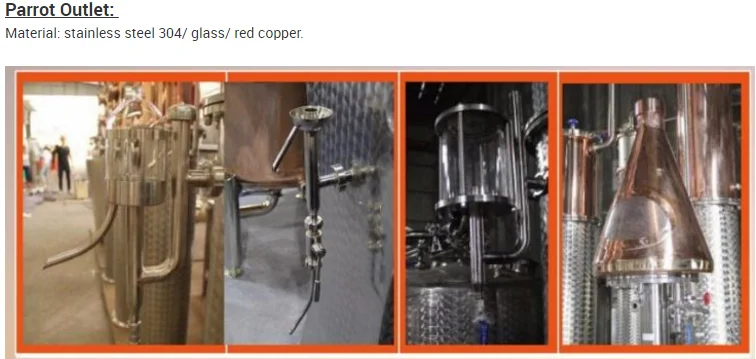

| SS parrot outlet | |

| Come with a CIP Cleaning Pump and all necessary SS CIP cleaning piping lines etc. | |

| Steam requirment: 50Kg/Hr | |

| Production time: 4 hours | |

| Max alcohol reached to 85%/ 170 Proof |

Copper Distiller Industrial Alcohol Whisky Distillation Equipment

Maximize your production capabilities with our Copper Distiller, specifically engineered for industrial alcohol and whisky distillation. This premium distillery equipment combines traditional craftsmanship with modern technology, making it ideal for large-scale operations in any whisky distillery.

Constructed from high-quality copper, this Industrial Distillation Equipment ensures exceptional heat conductivity and efficiency, allowing for precise temperature control and optimal flavor extraction. Its robust design not only enhances durability but also provides a classic aesthetic that elevates your distillation setup.

Main Features:

1.Advanced alcohol distillation equipment for high-volume production

2.Superior copper distiller design for optimal performance and flavor retention

3.Ideal for both whisky and other spirit distillation applications

4.Built to withstand the demands of industrial use while ensuring ease of operation

5.Comprehensive solution for all your distillery needs

Elevate your distillation process with our Copper Distiller, the perfect choice for any serious distiller looking to enhance their whisky production and overall efficiency.

Parameter:

| Specification | 500L working capacity pot; all stainless steel pot |

| SS Steam jacketed and insulated | |

| with 219mm handhole with DN51 outlet and valve | |

| With top agitator (explosion proof CE approved motor) | |

| Motor Power: 0.75KW / 60rpm | |

| Copper Cu12200 Gooseneck, 3mm thickness | |

| 300mm Copper Distillation Column, 4 plates copper distillation, each plate has CIP ball and drain valves. | |

| 300mm SS Dephlegmator on the top of column | |

| 300mm SS Condenser | |

| 2 pcs SS Tube Legs | |

| SS parrot outlet | |

| Come with a CIP Cleaning Pump and all necessary SS CIP cleaning piping lines etc. | |

| Steam requirment: 50Kg/Hr | |

| Production time: 4 hours | |

| Max alcohol reached to 85%/ 170 Proof |

| Material | red copper | ||

| Size | 2000L | ||

| Shape | dish top and bottom | ||

| Heating method | Steam | ||

| Structure | Jacket with PU insulation | ||

| Accessories | Top with agitator,ex-proof motor with UL/CE/CSA approved,CIP balls,pressure gauge,relief valve,manway and so on | ||

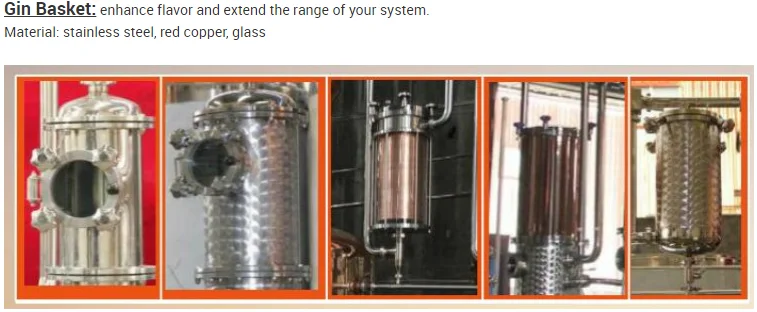

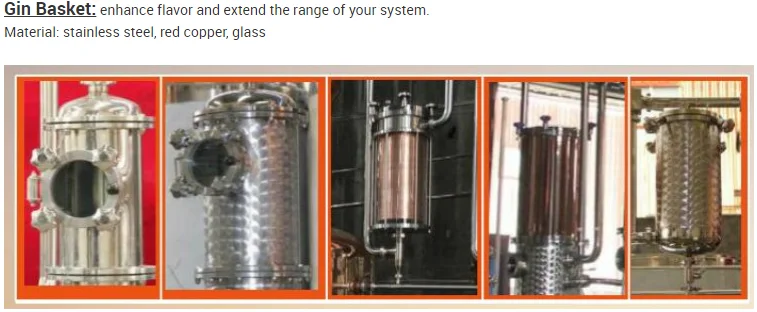

All bubble caps and screw are made of T2 grade red copper, the screw is designed by our company without dead corner and 100% meets sanitary standard.

Size: DN26/DN38/DN45/DN52/DN65/DN76

on the top of distillation column that sends vapor back toward the boiler.

Material: Stainless steel 304/ red copper with flange connection.

Structure: tube type jeat exchanger with cooling water inlet and outlet.

A heat exchanger in which hot vapors are cooled and condensed into liquid.

Material: stainless steel 304/ red copper and connected by flange.

All support are made of stainless steel 304, and we also can use storage tank as support.

All the CIP centrifugal pump is ex-proof with UL/ CSA/ CE certificate.

And we can supply hand valve and automatic valve.

| Material | red copper | ||

| Size | 2000L | ||

| Shape | dish top and bottom | ||

| Heating method | Steam | ||

| Structure | Jacket with PU insulation | ||

| Accessories | Top with agitator,ex-proof motor with UL/CE/CSA approved,CIP balls,pressure gauge,relief valve,manway and so on | ||

All bubble caps and screw are made of T2 grade red copper, the screw is designed by our company without dead corner and 100% meets sanitary standard.

Size: DN26/DN38/DN45/DN52/DN65/DN76

on the top of distillation column that sends vapor back toward the boiler.

Material: Stainless steel 304/ red copper with flange connection.

Structure: tube type jeat exchanger with cooling water inlet and outlet.

A heat exchanger in which hot vapors are cooled and condensed into liquid.

Material: stainless steel 304/ red copper and connected by flange.

All support are made of stainless steel 304, and we also can use storage tank as support.

All the CIP centrifugal pump is ex-proof with UL/ CSA/ CE certificate.

And we can supply hand valve and automatic valve.