| Availability: | |

|---|---|

| Quantity: | |

ZLSB-001

DYE

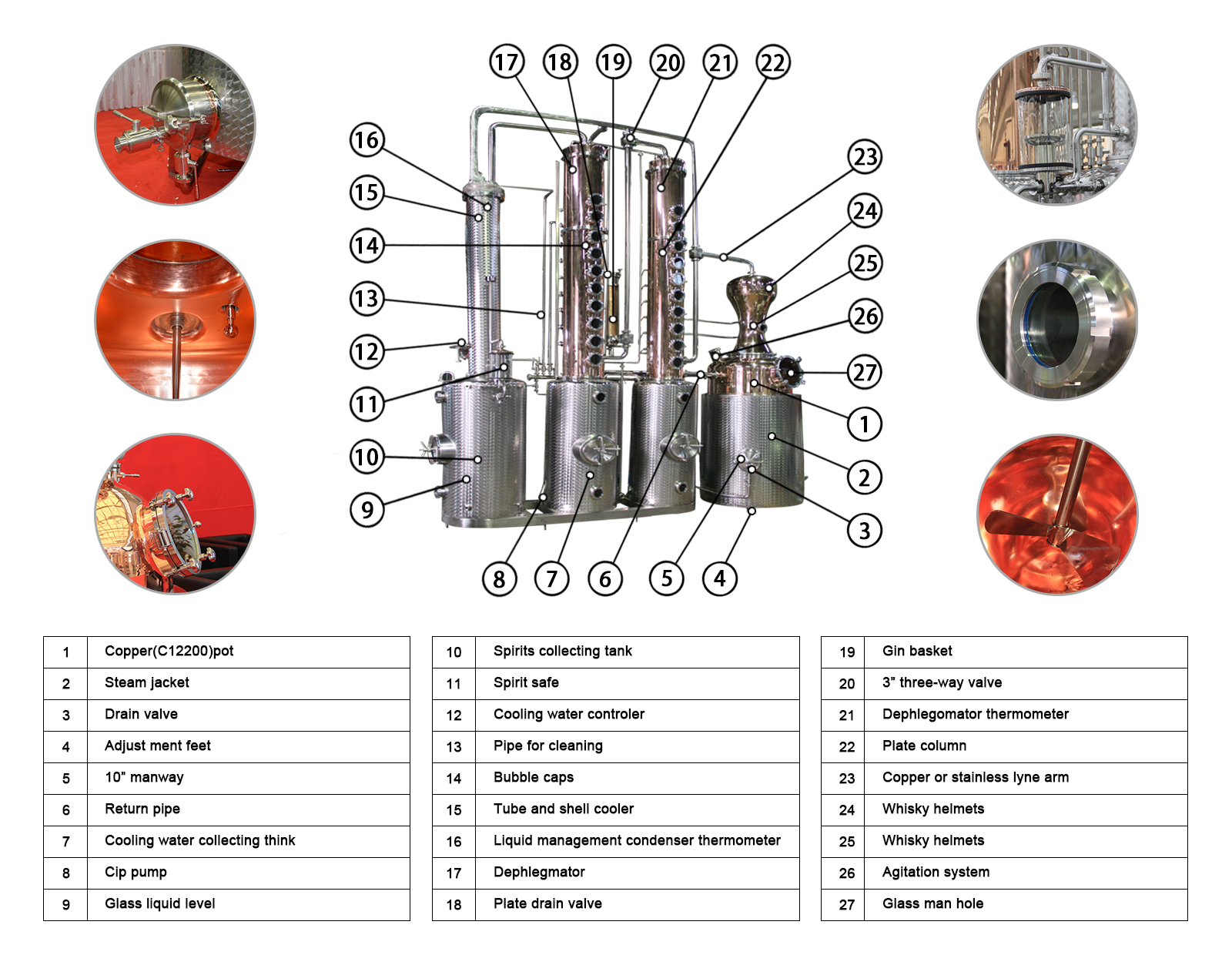

250Gal Vodka making machine copper gin distillation equipment

Elevate your distillation process with our 250 Gal Vodka Making Machine, expertly designed for producing high-quality spirits. This copper gin distillation equipment combines advanced technology with traditional craftsmanship, making it an essential addition to any distillery focused on efficiency and quality.

Constructed with premium materials, this distillation equipment ensures optimal heat conduction, enhancing the flavor and purity of your vodka. Its robust design allows for versatile applications, including both industrial distillation equipment and steam distillation equipment, catering to the needs of commercial distilleries.

Main Features:

1.Any size available

2.Customization service

3.Technology&drawing support

4.Swirl finish,satin finish or mirror finish

5.CIP pump and fittings are available

6.With beautiful appearance and high sanitary level.

7.with 3A,CE, UL,CSA,PED, SGS,TUV,ISO9001 certificates

8.High-quality copper construction for superior heat efficiency and durability

9.Versatile design suitable for various distillation methods, including vacuum distillation equipment

10.User-friendly operation for seamless integration into your distilling workflow

11.Perfect for craft distillers and commercial operations alike

Parameter:

| Working capacity: | 100L-5000L |

| Total Volume: | working capacity*130%-150% |

| Voltage: | 200V-240V/380-440V/600V |

| Weight: | 100kg-3000kg |

| Material: | SUS3048/SUS316L/COPPER-C12200 |

| Motor: | 3-phase power,UL/CSA/CE/ATEX,or Customizable brand |

| Reducer: | NEMA Standard (Made in Italy);ICE Standard (Made in China) |

| Welding Technolog: | High purity argon arc welding |

| Heating Method: | Steam/Water bath/Oil/Electric/Firewood/Gas |

| Heating form: | Direct or indirect heating |

| Distillation method: | Liquid distillation by default, custom solid distillation can be customized |

| Running time: | 2-8h,Customizable continuous distillation |

| Shape: | Upper and lower heads/Customizable |

| Distilled products: | Gin/Whisky/Vodka/Brandy/Tequila/Rum/Bourbon |

| Optional module: | 1.Cooling water recycling system 2.Light system 3.Alcohol storage tank system(Head/Heart/Tail) |

Advantages:

Advantages:

(1) Designed with German technology & traditional Chinese distillation equipment, and feedback from several trials and foreign customers.

(2) Good sealing reduces waste , increase the wine yield (5%-10%) and improve quality.

(3) One machine and dual usage. It could make whisky,rum,brandy,tequila etc.by once running of the distiller.By twice distillation the alcohol content will up to 95% and it can also remove methanol.

(4) Fast heat conduction can save energy.The material of our distiller are thicker than stills offered by many other manufacturers. We use C12200 red copper as our copper material. It is a special material for pressure vessles and contains 99.9% pure copper, which makes good performance on heat treatment.

(5) Less waste and save labor. also easy to operate and control

(6) The material can be grains,fruits,molases,low content alcohol.

(7) The equipment is made of stainless steel and copper, with beautiful appearance and high sanitary level.

(8) Save floor space and greatly improve the hygiene of the entire distillation site for you.

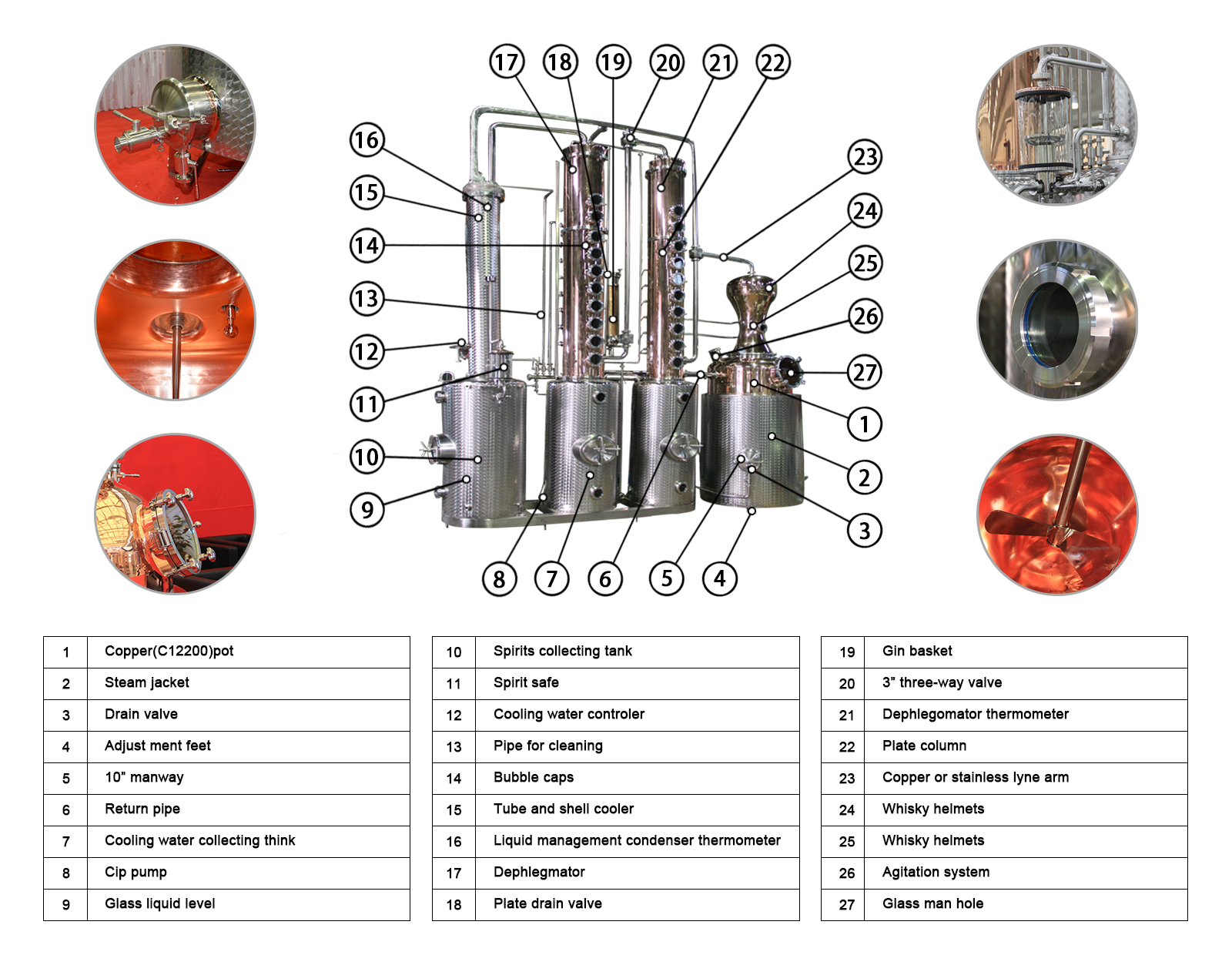

250Gal Vodka making machine copper gin distillation equipment

Elevate your distillation process with our 250 Gal Vodka Making Machine, expertly designed for producing high-quality spirits. This copper gin distillation equipment combines advanced technology with traditional craftsmanship, making it an essential addition to any distillery focused on efficiency and quality.

Constructed with premium materials, this distillation equipment ensures optimal heat conduction, enhancing the flavor and purity of your vodka. Its robust design allows for versatile applications, including both industrial distillation equipment and steam distillation equipment, catering to the needs of commercial distilleries.

Main Features:

1.Any size available

2.Customization service

3.Technology&drawing support

4.Swirl finish,satin finish or mirror finish

5.CIP pump and fittings are available

6.With beautiful appearance and high sanitary level.

7.with 3A,CE, UL,CSA,PED, SGS,TUV,ISO9001 certificates

8.High-quality copper construction for superior heat efficiency and durability

9.Versatile design suitable for various distillation methods, including vacuum distillation equipment

10.User-friendly operation for seamless integration into your distilling workflow

11.Perfect for craft distillers and commercial operations alike

Parameter:

| Working capacity: | 100L-5000L |

| Total Volume: | working capacity*130%-150% |

| Voltage: | 200V-240V/380-440V/600V |

| Weight: | 100kg-3000kg |

| Material: | SUS3048/SUS316L/COPPER-C12200 |

| Motor: | 3-phase power,UL/CSA/CE/ATEX,or Customizable brand |

| Reducer: | NEMA Standard (Made in Italy);ICE Standard (Made in China) |

| Welding Technolog: | High purity argon arc welding |

| Heating Method: | Steam/Water bath/Oil/Electric/Firewood/Gas |

| Heating form: | Direct or indirect heating |

| Distillation method: | Liquid distillation by default, custom solid distillation can be customized |

| Running time: | 2-8h,Customizable continuous distillation |

| Shape: | Upper and lower heads/Customizable |

| Distilled products: | Gin/Whisky/Vodka/Brandy/Tequila/Rum/Bourbon |

| Optional module: | 1.Cooling water recycling system 2.Light system 3.Alcohol storage tank system(Head/Heart/Tail) |

Advantages:

Advantages:

(1) Designed with German technology & traditional Chinese distillation equipment, and feedback from several trials and foreign customers.

(2) Good sealing reduces waste , increase the wine yield (5%-10%) and improve quality.

(3) One machine and dual usage. It could make whisky,rum,brandy,tequila etc.by once running of the distiller.By twice distillation the alcohol content will up to 95% and it can also remove methanol.

(4) Fast heat conduction can save energy.The material of our distiller are thicker than stills offered by many other manufacturers. We use C12200 red copper as our copper material. It is a special material for pressure vessles and contains 99.9% pure copper, which makes good performance on heat treatment.

(5) Less waste and save labor. also easy to operate and control

(6) The material can be grains,fruits,molases,low content alcohol.

(7) The equipment is made of stainless steel and copper, with beautiful appearance and high sanitary level.

(8) Save floor space and greatly improve the hygiene of the entire distillation site for you.