| Availability: | |

|---|---|

| Quantity: | |

The mixing tank is widely used in medicine, coatings, building materials, chemicals, pigments, resins, food, scientific research and other industries. The Agitator Tank can be made of carbon steel, stainless steel and other materials according to the process requirements of the user's products, and set up heating and cooling devices to meet different process and production needs. Heating forms include jacket electric heating and coil heating.

The stirring tank has the advantages of reasonable structure design, advanced technology, durability, simple operation and convenient use. It is an ideal chemical equipment with less investment, quick production and high income.

Optimize your mixing process with our versatile 100L-3000L Mixing Tanks, designed for a wide range of applications in medicine, food production, pharmaceuticals, and chemical industries. These agitator tanks are engineered for precision blending and consistent stirring, ensuring high-quality results every time. Perfect for large and small-scale production, they provide efficient mixing solutions for liquids, powders, and viscous substances.

Crafted from premium stainless steel, these blending tanks offer exceptional durability, corrosion resistance, and ease of cleaning—essential for maintaining hygienic standards in pharmaceutical and food processing environments. Whether you're mixing medications, food ingredients, or chemical compounds, these chemical mixing tanks deliver uniform blending with minimal effort.

Equipped with powerful pharmaceutical agitators, these tanks ensure even blending and thorough agitation for uniform product consistency.

Our mixing vessels for the pharmaceutical industry are designed for a wide range of applications, from liquid medicines to pharmaceutical powders and food ingredients.

Ideal for blending a variety of food ingredients, offering superior performance and efficiency in food processing.

These tanks feature electric agitators with adjustable speeds, allowing for precise control of mixing operations, ensuring optimal results.

Perfect for handling chemical mixtures, our tanks provide reliable agitation for a wide array of chemical and pharmaceutical products.

The agitator in the tank is designed for durability and easy maintenance, ensuring long-lasting and reliable performance in demanding environments.

1.Pharmaceutical Mixing Vessels: Ideal for creating consistent drug formulations.

2.Food Processing: Perfect for blending food ingredients like sauces, pastes, and beverages.

3.Chemical Industry: Suitable for mixing chemicals and liquids that require uniformity.

4.Medicine Tank: Essential for mixing medicine formulations and ensuring quality standards.

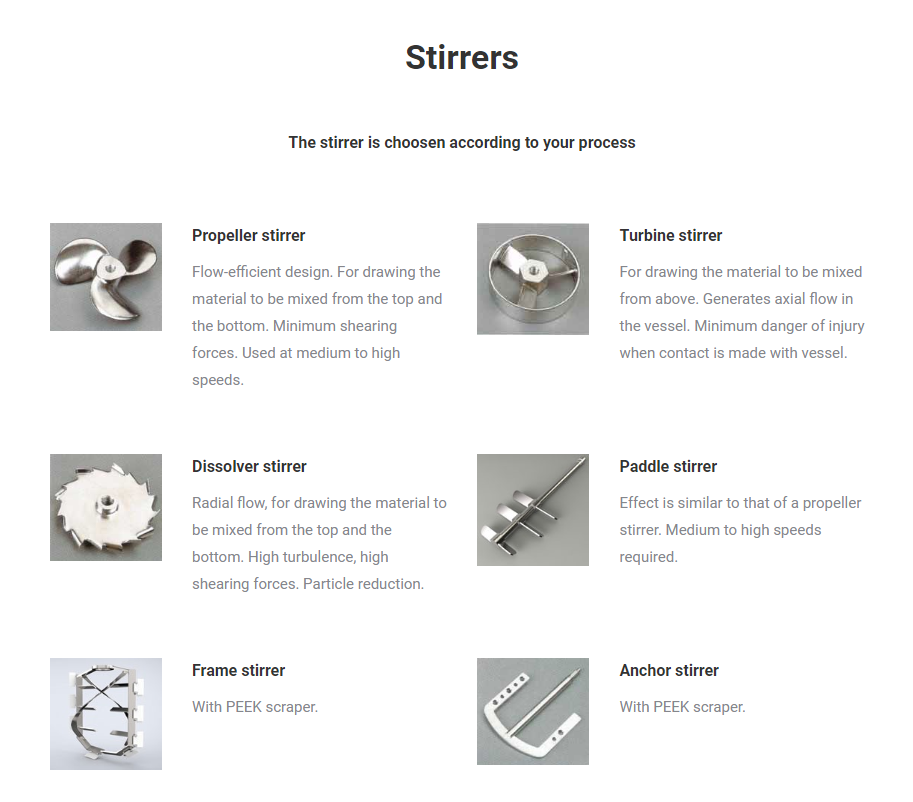

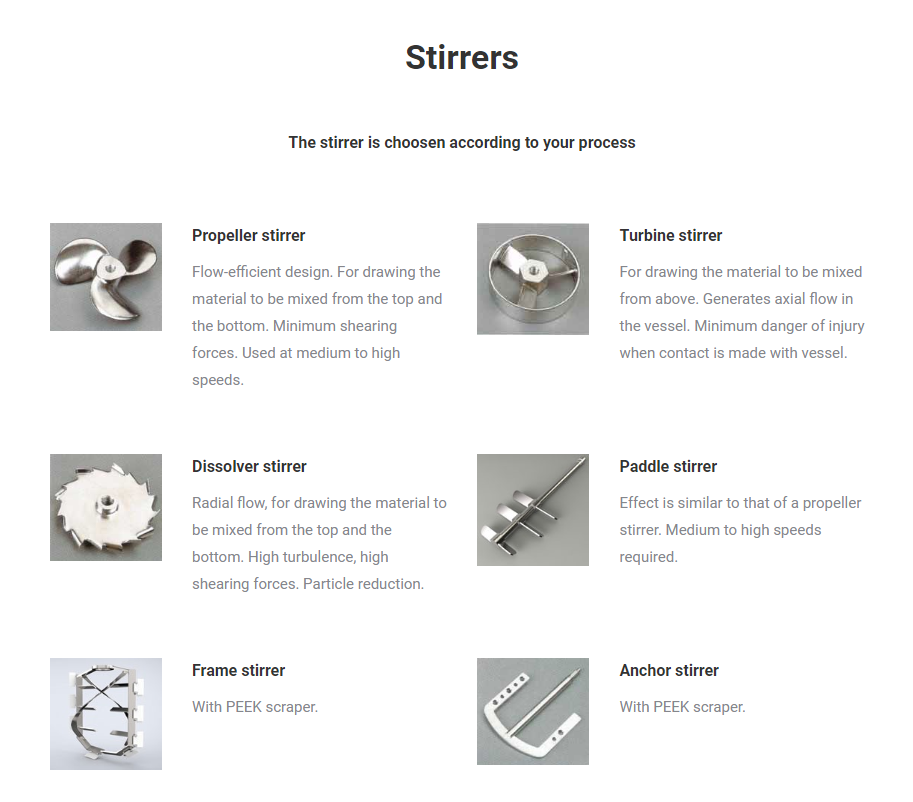

The mixing tank is composed of a stirring tank body, a stirring tank cover, a stirrer, a support, a transmission device, a shaft sealing device, etc., and a heating device or a cooling device can also be configured according to the process requirements.

The stirring tank body and the stirring tank cover can be connected by flange sealing or welding. The stirring tank body and stirring tank cover can open process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, and safe venting according to the process requirements.

Our mixing tanks offer superior pharmaceutical mixing efficiency, robust construction, and versatile functionality. Whether for pharmaceutical, chemical, or food processing applications, our tanks provide high-end technology and reliability, ensuring your products meet the highest quality standards. The integrated agitators make these tanks perfect for large-scale production, while their customizable size options (100L-3000L) allow for flexibility in any operational setting.

Enhance your production efficiency with our 100L-3000L Mixing Tanks, the perfect solution for pharmaceutical, food, and chemical industries requiring reliable and precise mixing technologies.

The mixing tank is widely used in medicine, coatings, building materials, chemicals, pigments, resins, food, scientific research and other industries. The Agitator Tank can be made of carbon steel, stainless steel and other materials according to the process requirements of the user's products, and set up heating and cooling devices to meet different process and production needs. Heating forms include jacket electric heating and coil heating.

The stirring tank has the advantages of reasonable structure design, advanced technology, durability, simple operation and convenient use. It is an ideal chemical equipment with less investment, quick production and high income.

Optimize your mixing process with our versatile 100L-3000L Mixing Tanks, designed for a wide range of applications in medicine, food production, pharmaceuticals, and chemical industries. These agitator tanks are engineered for precision blending and consistent stirring, ensuring high-quality results every time. Perfect for large and small-scale production, they provide efficient mixing solutions for liquids, powders, and viscous substances.

Crafted from premium stainless steel, these blending tanks offer exceptional durability, corrosion resistance, and ease of cleaning—essential for maintaining hygienic standards in pharmaceutical and food processing environments. Whether you're mixing medications, food ingredients, or chemical compounds, these chemical mixing tanks deliver uniform blending with minimal effort.

Equipped with powerful pharmaceutical agitators, these tanks ensure even blending and thorough agitation for uniform product consistency.

Our mixing vessels for the pharmaceutical industry are designed for a wide range of applications, from liquid medicines to pharmaceutical powders and food ingredients.

Ideal for blending a variety of food ingredients, offering superior performance and efficiency in food processing.

These tanks feature electric agitators with adjustable speeds, allowing for precise control of mixing operations, ensuring optimal results.

Perfect for handling chemical mixtures, our tanks provide reliable agitation for a wide array of chemical and pharmaceutical products.

The agitator in the tank is designed for durability and easy maintenance, ensuring long-lasting and reliable performance in demanding environments.

1.Pharmaceutical Mixing Vessels: Ideal for creating consistent drug formulations.

2.Food Processing: Perfect for blending food ingredients like sauces, pastes, and beverages.

3.Chemical Industry: Suitable for mixing chemicals and liquids that require uniformity.

4.Medicine Tank: Essential for mixing medicine formulations and ensuring quality standards.

The mixing tank is composed of a stirring tank body, a stirring tank cover, a stirrer, a support, a transmission device, a shaft sealing device, etc., and a heating device or a cooling device can also be configured according to the process requirements.

The stirring tank body and the stirring tank cover can be connected by flange sealing or welding. The stirring tank body and stirring tank cover can open process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, and safe venting according to the process requirements.

Our mixing tanks offer superior pharmaceutical mixing efficiency, robust construction, and versatile functionality. Whether for pharmaceutical, chemical, or food processing applications, our tanks provide high-end technology and reliability, ensuring your products meet the highest quality standards. The integrated agitators make these tanks perfect for large-scale production, while their customizable size options (100L-3000L) allow for flexibility in any operational setting.

Enhance your production efficiency with our 100L-3000L Mixing Tanks, the perfect solution for pharmaceutical, food, and chemical industries requiring reliable and precise mixing technologies.