| Availability: | |

|---|---|

| Quantity: | |

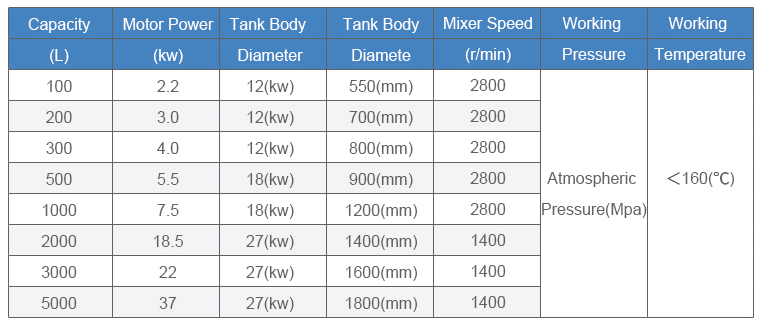

High Shear Emulsification Tank Homogeneous Tank Mixing Tank Customization

The emulsification tank is suitable for the production of cosmetic, medicine, food, chemical, dyeing, printing ink and other industrial products, especially for the preparation of materials with high viscosity and high solid content.

Working Principle:

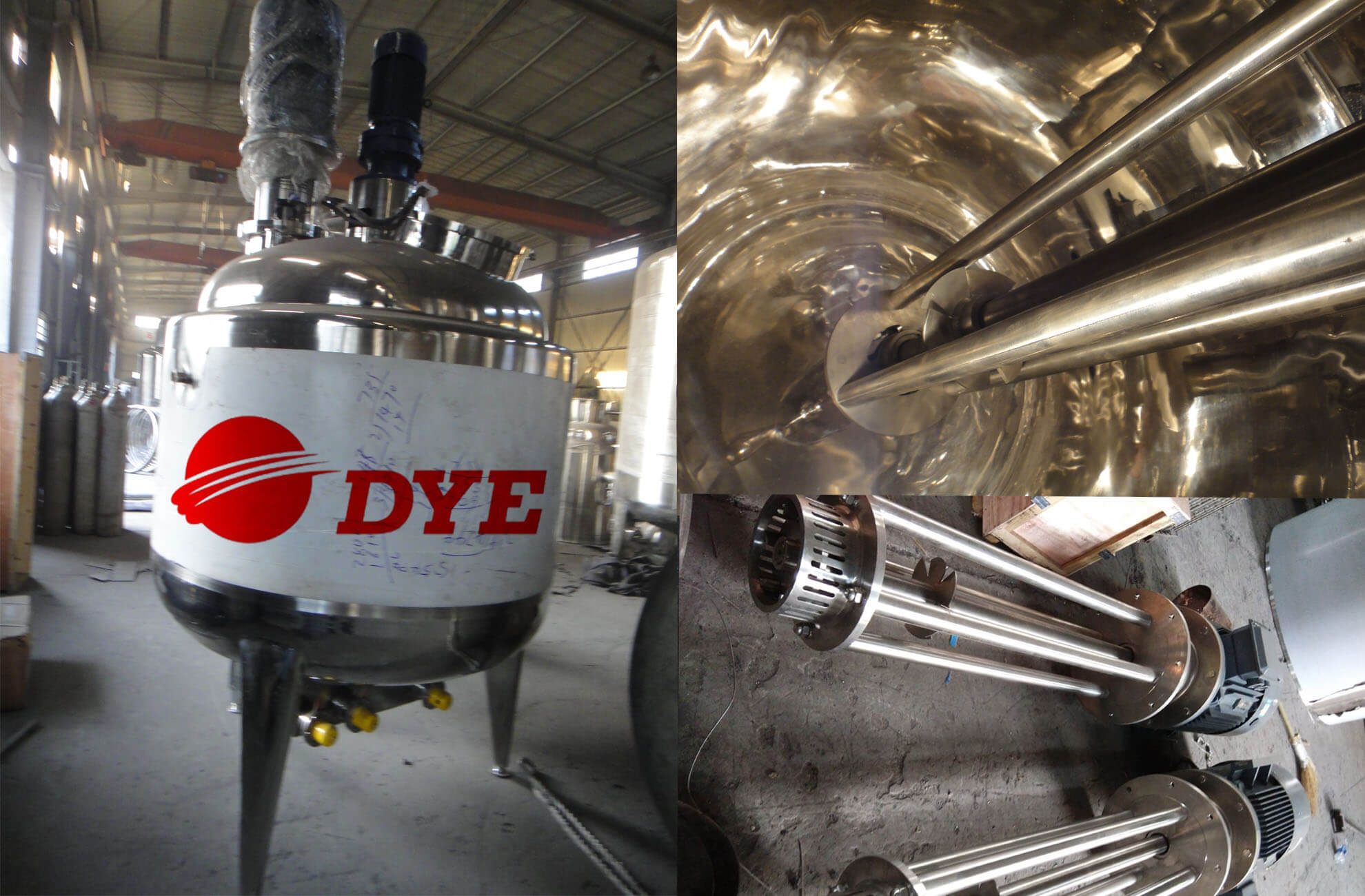

Under the action of the centrifugal force generated by the high-speed and strong rotating rotor, the stainless steel emulsification tank throws the material from the radial direction into the narrow and precise gap between the stator and the rotor, and is simultaneously subjected to centrifugal extrusion, impact and other forces. Disperse, mix and emulsify materials.

Features:

1. The high shear emulsification tank has the advantages of compact structure, small size, light weight, convenient operation, low noise, stable operation, good homogeneity, high production efficiency, convenient cleaning and high degree of automation.

2. In the production process, the medium is not ground, and it integrates high-speed shearing, dispersion, homogenization, mixing and pulverization.

3. Equipped with a CIP cleaning system, the contact part between the container and the material is made of SUS316L material, and the inner surface is mirror polished (sanitary grade).

4. The high shear emulsification tank also has the functions of heating, cooling, heat preservation and stirring.

5. The tank body is designed with feeding port, pure water port, discharging port, sampling port, etc., which can provide the whole process of emulsification process.

6. After emulsification, direct steam can be turned on to achieve the function of sterilization and disinfection. At the same time, after the high temperature emulsification process is completed. If cooling is required, the drain valve can be opened after cooling.

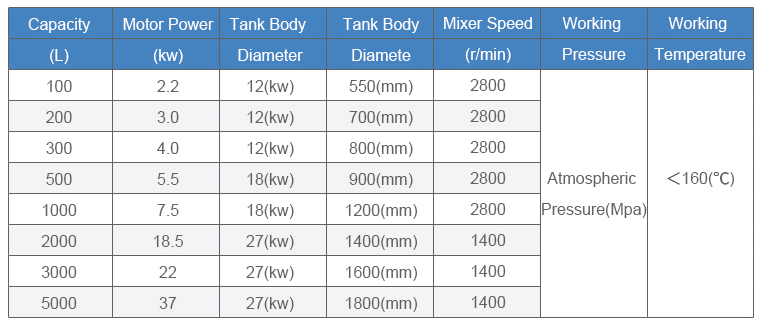

High Shear Emulsification Tank Homogeneous Tank Mixing Tank Customization

The emulsification tank is suitable for the production of cosmetic, medicine, food, chemical, dyeing, printing ink and other industrial products, especially for the preparation of materials with high viscosity and high solid content.

Working Principle:

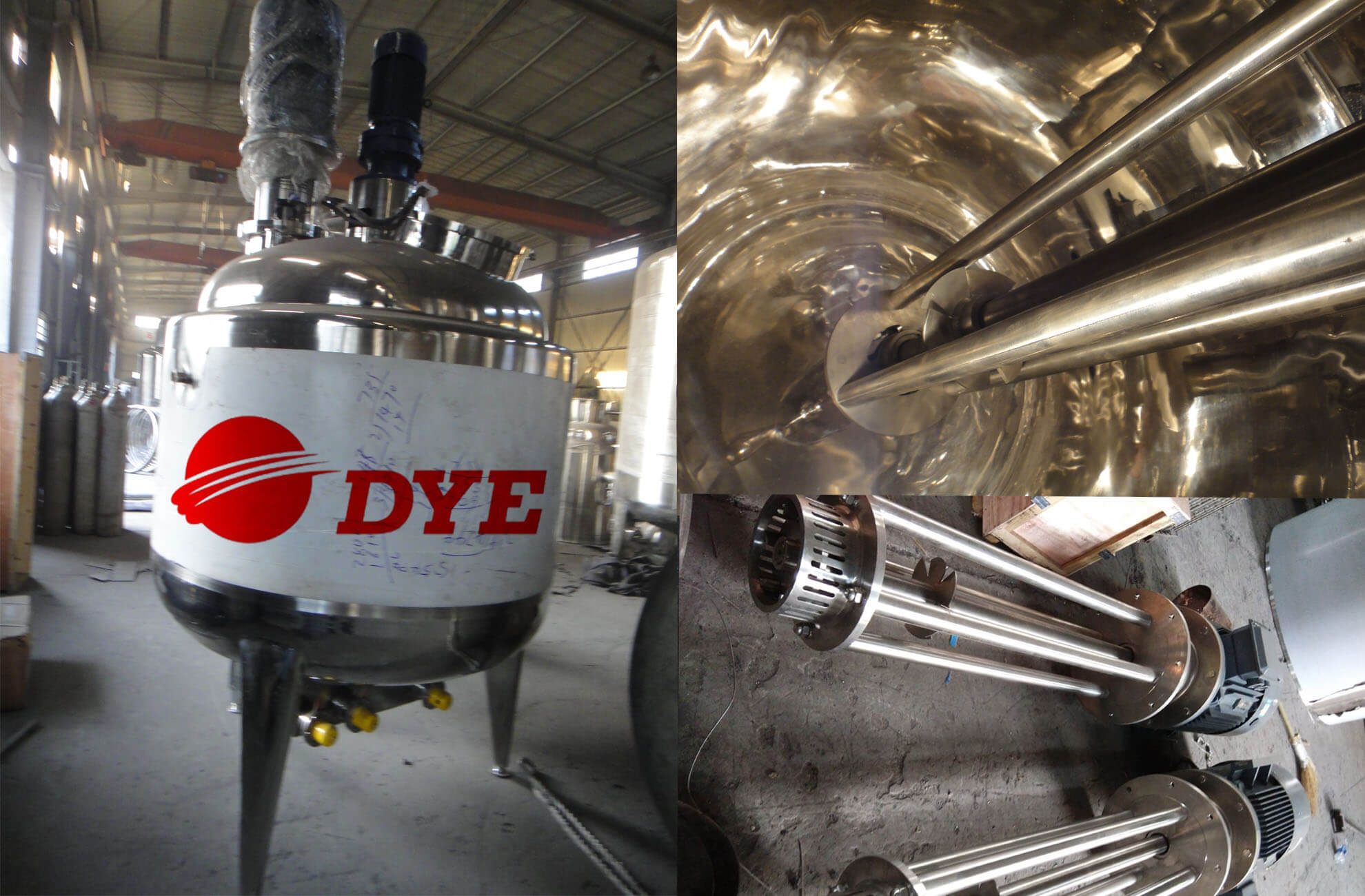

Under the action of the centrifugal force generated by the high-speed and strong rotating rotor, the stainless steel emulsification tank throws the material from the radial direction into the narrow and precise gap between the stator and the rotor, and is simultaneously subjected to centrifugal extrusion, impact and other forces. Disperse, mix and emulsify materials.

Features:

1. The high shear emulsification tank has the advantages of compact structure, small size, light weight, convenient operation, low noise, stable operation, good homogeneity, high production efficiency, convenient cleaning and high degree of automation.

2. In the production process, the medium is not ground, and it integrates high-speed shearing, dispersion, homogenization, mixing and pulverization.

3. Equipped with a CIP cleaning system, the contact part between the container and the material is made of SUS316L material, and the inner surface is mirror polished (sanitary grade).

4. The high shear emulsification tank also has the functions of heating, cooling, heat preservation and stirring.

5. The tank body is designed with feeding port, pure water port, discharging port, sampling port, etc., which can provide the whole process of emulsification process.

6. After emulsification, direct steam can be turned on to achieve the function of sterilization and disinfection. At the same time, after the high temperature emulsification process is completed. If cooling is required, the drain valve can be opened after cooling.