| Availability: | |

|---|---|

| Quantity: | |

DYE

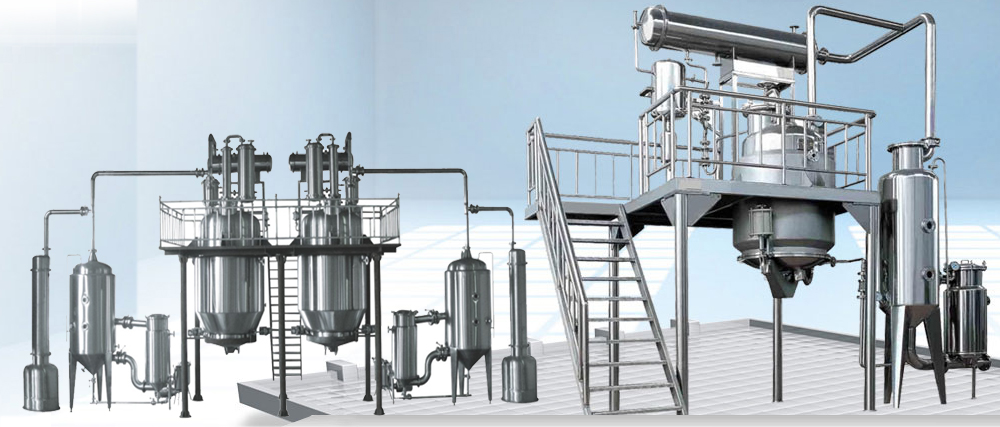

Heat Reflux Concentration And Extraction Equipment Herbal Extraction Tank

The heat reflux concentration and extraction equipment is applicable to extraction and concentration processes of plants, herbal medicine, traditional Chinese medicine and animal. It changes the traditional technology of first carrying out extraction and then concentration that it can simultaneously carry out extraction and concentration. The whole set unit can realize low temperature extraction in a real sense under negative pressure, normal pressure and positive pressure.

Advantage:

1. The ointment collecting rate is 10~15% higher than that of the multifunctional extracting tank.The effective components in the ointment are 1 time higher. During the extraction, the hot solvent will be continuously added to the medicine surface and pass the medicine materials layer from upward to downward to dissolve the effective components in the medicine materials. The content of solute in the medicine and the mass of solute in the solvent keep high gradient, and the solute in the medicine will be rapidly dissolved until it is completely dissolved. Therefore, the extracting rate of effective components is high. The concentration is completed in another sealed equipment, so the loss is small and the conversion rate is high. Therefore, the ointment collecting rate is high and the content of effective components in the ointment is high.

2. As the solute is rapidly dissolved, the extracting time is short, and the concentration and extraction are carried out simultaneously, it only takes 7~8hours to make the medicine into concentrated ointment.Thus the utility efficiency of the

equipment is very high.

3. The investment is very economic due to the simple equipment, small landing area and high utility efficiency of the equipment.

4. The solvent is added only once during the extraction and can be reused in a set of closed equipment. The solvent in the medicine residue can be substantially recovered. Therefore, the solvent consumption is 30% fewer than that of multiple extracting tanks & the consumption rate can reduce 50~70%.This has made it successful for the solvent to extract and purify the effective components in traditional Chinese medicine.

5. As the twice steam produced during the concentration acts as the heat source for extraction, the extracting liquid pumped into the concentrator has same temperature as that during the concentration. Therefore over 50% of steam can be saved. The operation is simple, which reduces operators.

Parameter:

| Model | HR-1 | HR-2 | HR-3 | HR-4 |

| Extraction tank volume(m³) | 1 | 2 | 3 | 6 |

| Concentrator volume(m³) | 0.5 | 1 | 1.5 | 2.5 |

| Extraction temperature(℃) | 78~83 | |||

| Extraction time(hours/batch) | 7~8 | |||

| Vacuum degree(Mpa) | 0.05~0.08 | |||

| Use pressure(Mpa) | 0.08~0.2 | |||

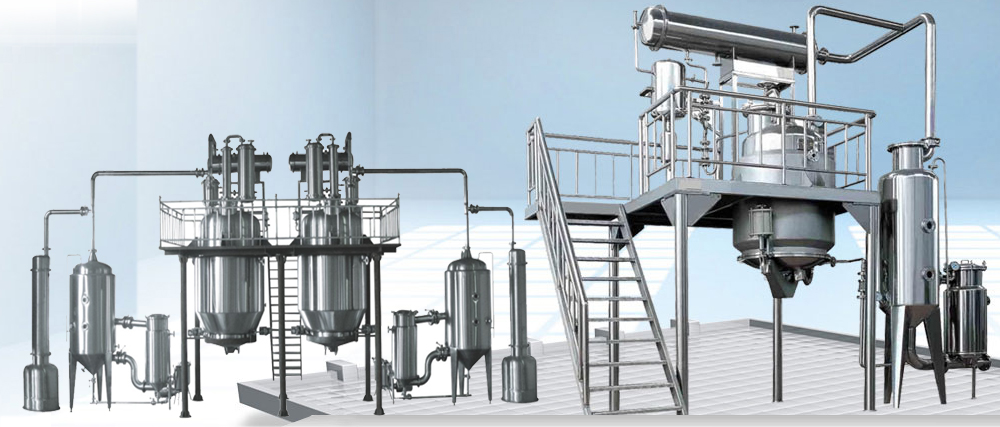

Heat Reflux Concentration And Extraction Equipment Herbal Extraction Tank

The heat reflux concentration and extraction equipment is applicable to extraction and concentration processes of plants, herbal medicine, traditional Chinese medicine and animal. It changes the traditional technology of first carrying out extraction and then concentration that it can simultaneously carry out extraction and concentration. The whole set unit can realize low temperature extraction in a real sense under negative pressure, normal pressure and positive pressure.

Advantage:

1. The ointment collecting rate is 10~15% higher than that of the multifunctional extracting tank.The effective components in the ointment are 1 time higher. During the extraction, the hot solvent will be continuously added to the medicine surface and pass the medicine materials layer from upward to downward to dissolve the effective components in the medicine materials. The content of solute in the medicine and the mass of solute in the solvent keep high gradient, and the solute in the medicine will be rapidly dissolved until it is completely dissolved. Therefore, the extracting rate of effective components is high. The concentration is completed in another sealed equipment, so the loss is small and the conversion rate is high. Therefore, the ointment collecting rate is high and the content of effective components in the ointment is high.

2. As the solute is rapidly dissolved, the extracting time is short, and the concentration and extraction are carried out simultaneously, it only takes 7~8hours to make the medicine into concentrated ointment.Thus the utility efficiency of the

equipment is very high.

3. The investment is very economic due to the simple equipment, small landing area and high utility efficiency of the equipment.

4. The solvent is added only once during the extraction and can be reused in a set of closed equipment. The solvent in the medicine residue can be substantially recovered. Therefore, the solvent consumption is 30% fewer than that of multiple extracting tanks & the consumption rate can reduce 50~70%.This has made it successful for the solvent to extract and purify the effective components in traditional Chinese medicine.

5. As the twice steam produced during the concentration acts as the heat source for extraction, the extracting liquid pumped into the concentrator has same temperature as that during the concentration. Therefore over 50% of steam can be saved. The operation is simple, which reduces operators.

Parameter:

| Model | HR-1 | HR-2 | HR-3 | HR-4 |

| Extraction tank volume(m³) | 1 | 2 | 3 | 6 |

| Concentrator volume(m³) | 0.5 | 1 | 1.5 | 2.5 |

| Extraction temperature(℃) | 78~83 | |||

| Extraction time(hours/batch) | 7~8 | |||

| Vacuum degree(Mpa) | 0.05~0.08 | |||

| Use pressure(Mpa) | 0.08~0.2 | |||