| Availability: | |

|---|---|

| Quantity: | |

DYE

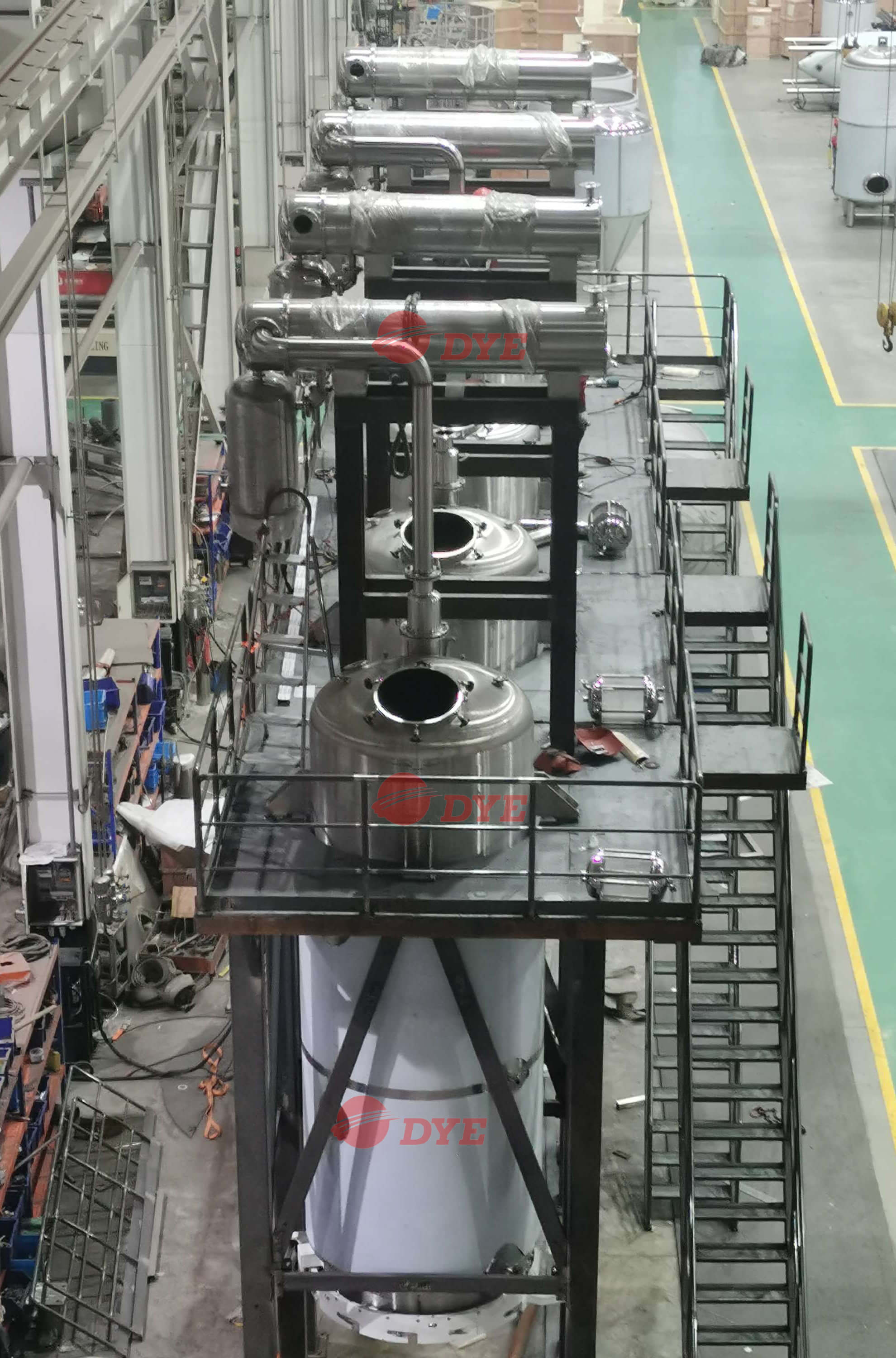

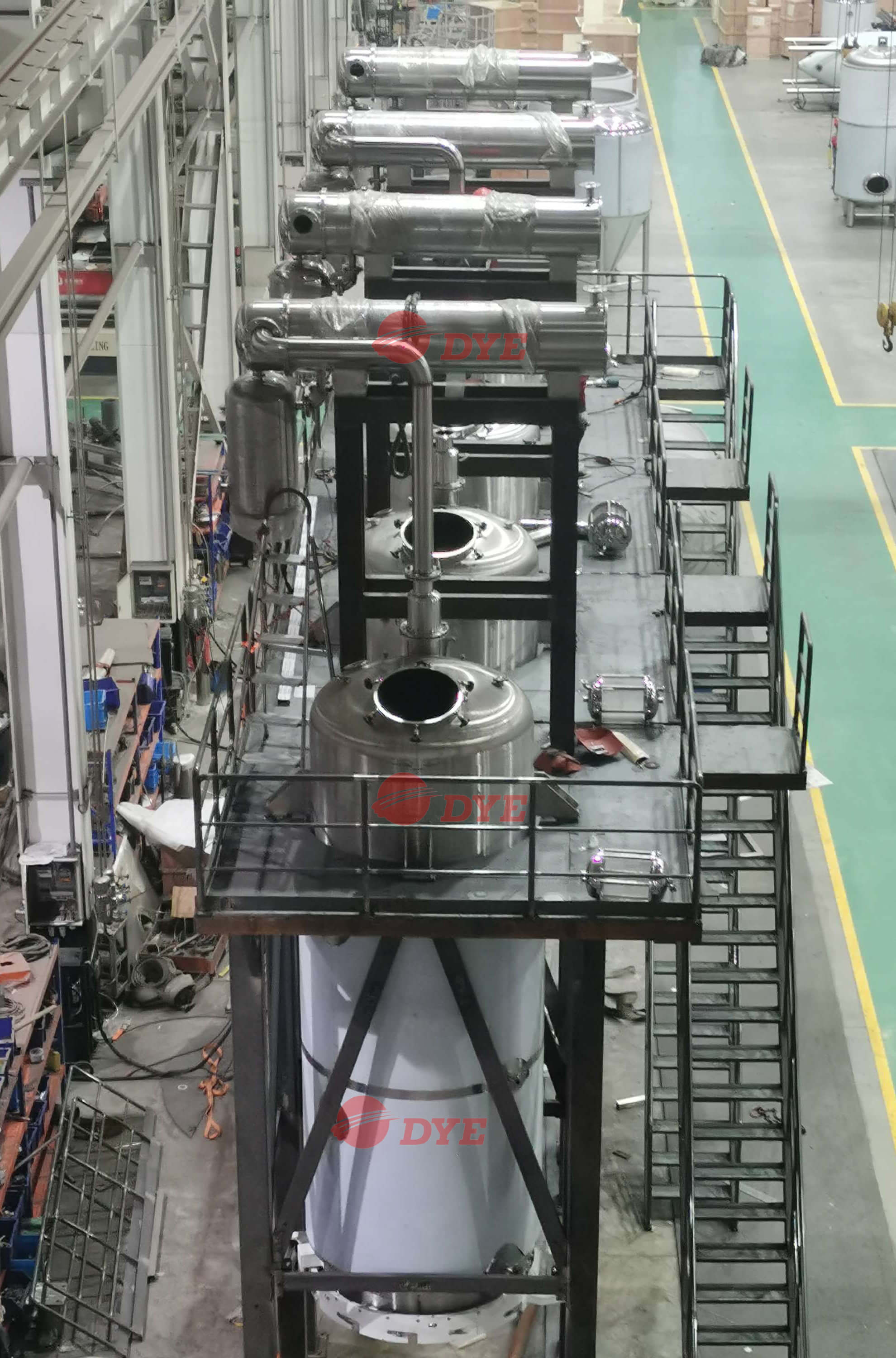

Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank – High-Efficiency Extraction Equipment for Cannabis, Hemp, and Herbal Applications

Vertical cylinder extracting tank can be used in Chinese medicine, food and chemical industries to normal pressure, micro-pressure, water frying, warm soaking, heat cycling, cycling leaking, redolent oil extract and organically solvent recycle.

The Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank is a state-of-the-art extraction equipment designed to provide high-efficiency extraction of cannabinoids, terpenes, essential oils, and other valuable compounds from cannabis, hemp, and herbs. Featuring a vertical cylindrical design, this extracting tank maximizes solvent flow and promotes even extraction, ensuring optimal yields and superior quality extracts.

Built for both small and large-scale operations, the Vertical Cylinder Extraction Tank is ideal for commercial cannabis and hemp extraction, as well as herbal extractions for essential oils. Its robust construction and precision controls allow for reliable performance, producing consistent results with each extraction cycle.

1. quick-open slag discharge door, safety and reliable, it’s easy to discharge slag.

2. high efficiency and simple operating, also has ClP cleaning system that is in accordance with GMP standards.

3. material adopts high quality stainless steel 304/316L.

4. Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank optimized for efficient extraction of cannabis, hemp, and herb compounds

5. Vertical cylindrical design enhances solvent circulation, improving extraction efficiency and maximizing yields

6. High-quality extracting tanks built for durability and long-term performance in industrial extraction processes

7. Suitable for large-scale operations, with scalable options available for varying production needs

8. Provides precise control over the extraction process, ensuring consistent and high-quality results with every batch

9. Versatile extraction equipment suitable for a variety of herbs and botanicals beyond cannabis and hemp

10. Ideal for use in commercial and industrial extraction facilities, as well as research labs

11. Efficient Extractor for producing top-quality plant extracts and concentrates

The Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank delivers exceptional performance and value for anyone involved in cannabis, hemp, or herbal extraction. Achieve high yields and precise extractions with this reliable and advanced extracting tank.

Parameter:

| Model | TQ-Z-1.0 | TQ-Z-2.0 | TQ-Z-3.0 | TQ-Z-6.0 | TQ-Z-8.0 | TQ-Z-10 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Design pressure in the tank(Mpa) | 0.09 | |||||

| Design pressure in the jacket(Mpa) | 0.3 | |||||

| Compressed air pressure(Mpa) | 0.6-0.7 | |||||

| Diameter of feeding inlet(mm) | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area(㎡) | 3 | 4.7 | 6 | 7.5 | 9.5 | 12 |

| Condensing area(㎡) | 4 | 4 | 12 | 5 | 8 | 20 |

| Cooling area(㎡) | 1 | 1 | 1.5 | 2 | 2 | 3 |

| Filtering area(㎡) | 3 | 3 | 3 | 5 | 5 | 6 |

| Diameter of residue discharging door(mm) | 800 | 800 | 1000 | 1000 | 1200 | 1200 |

| Energy consumption(kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

| Equipment weigh(kg) | 1800 | 2050 | 2400 | 3025 | 4030 | 6500 |

Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank – High-Efficiency Extraction Equipment for Cannabis, Hemp, and Herbal Applications

Vertical cylinder extracting tank can be used in Chinese medicine, food and chemical industries to normal pressure, micro-pressure, water frying, warm soaking, heat cycling, cycling leaking, redolent oil extract and organically solvent recycle.

The Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank is a state-of-the-art extraction equipment designed to provide high-efficiency extraction of cannabinoids, terpenes, essential oils, and other valuable compounds from cannabis, hemp, and herbs. Featuring a vertical cylindrical design, this extracting tank maximizes solvent flow and promotes even extraction, ensuring optimal yields and superior quality extracts.

Built for both small and large-scale operations, the Vertical Cylinder Extraction Tank is ideal for commercial cannabis and hemp extraction, as well as herbal extractions for essential oils. Its robust construction and precision controls allow for reliable performance, producing consistent results with each extraction cycle.

1. quick-open slag discharge door, safety and reliable, it’s easy to discharge slag.

2. high efficiency and simple operating, also has ClP cleaning system that is in accordance with GMP standards.

3. material adopts high quality stainless steel 304/316L.

4. Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank optimized for efficient extraction of cannabis, hemp, and herb compounds

5. Vertical cylindrical design enhances solvent circulation, improving extraction efficiency and maximizing yields

6. High-quality extracting tanks built for durability and long-term performance in industrial extraction processes

7. Suitable for large-scale operations, with scalable options available for varying production needs

8. Provides precise control over the extraction process, ensuring consistent and high-quality results with every batch

9. Versatile extraction equipment suitable for a variety of herbs and botanicals beyond cannabis and hemp

10. Ideal for use in commercial and industrial extraction facilities, as well as research labs

11. Efficient Extractor for producing top-quality plant extracts and concentrates

The Vertical Cylinder Type Herb Cannabis Hemp Extract Extraction Tank delivers exceptional performance and value for anyone involved in cannabis, hemp, or herbal extraction. Achieve high yields and precise extractions with this reliable and advanced extracting tank.

Parameter:

| Model | TQ-Z-1.0 | TQ-Z-2.0 | TQ-Z-3.0 | TQ-Z-6.0 | TQ-Z-8.0 | TQ-Z-10 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Design pressure in the tank(Mpa) | 0.09 | |||||

| Design pressure in the jacket(Mpa) | 0.3 | |||||

| Compressed air pressure(Mpa) | 0.6-0.7 | |||||

| Diameter of feeding inlet(mm) | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area(㎡) | 3 | 4.7 | 6 | 7.5 | 9.5 | 12 |

| Condensing area(㎡) | 4 | 4 | 12 | 5 | 8 | 20 |

| Cooling area(㎡) | 1 | 1 | 1.5 | 2 | 2 | 3 |

| Filtering area(㎡) | 3 | 3 | 3 | 5 | 5 | 6 |

| Diameter of residue discharging door(mm) | 800 | 800 | 1000 | 1000 | 1200 | 1200 |

| Energy consumption(kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

| Equipment weigh(kg) | 1800 | 2050 | 2400 | 3025 | 4030 | 6500 |